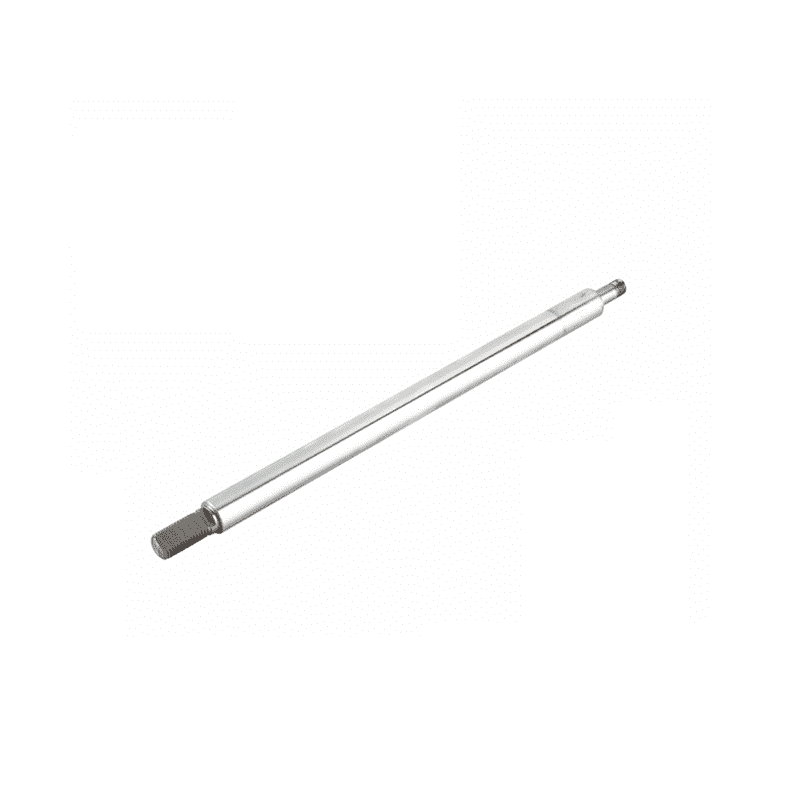

OEM Supply Cnc Machined Aluminum Rings - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. |

|

Diameter |

0.1-25mm |

|

Length |

Customization |

|

Roughness |

Ra0.4-Ra0.8 |

Available materials :

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface treatment:

|

Aluminum parts |

Stainless Steel parts |

Steel parts |

Brass parts |

|

Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

|

Color Anodized |

Passivating |

Oxide black |

chrome plating |

|

Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

|

Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

|

Brushing |

Electrophoresis black |

Carburized |

Powder coated |

|

Polishing |

Oxide black |

Heat treatment |

|

|

Chroming |

Powder Coated |

||

|

Heat Treatment |

Tempering |

Hardening |

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details

|

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for OEM Supply Cnc Machined Aluminum Rings - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong, The product will supply to all over the world, such as: Slovenia, Liberia, Lisbon, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

-

Discount Price Metal Lid Stamping Part - High ...

-

2020 New Style 4 Axis Cnc Horizontal Machining ...

-

8 Year Exporter Cnc Machining Aluminum Alloy -...

-

Manufacturer of Customise Aluminum Deep Drawing...

-

Factory Price Lathe Machine Parts - Cnc Micro ...

-

Big discounting Metal Cnc Parts - Premium Surf...