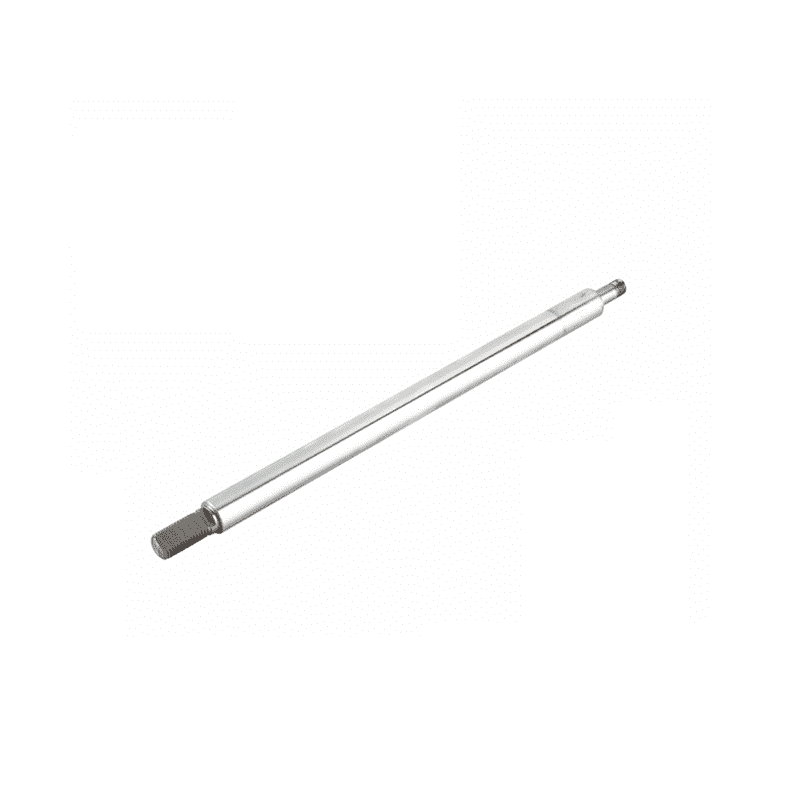

Manufacturing Companies for Deep Draw Process - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. |

|

Diameter |

0.1-25mm |

|

Length |

Customization |

|

Roughness |

Ra0.4-Ra0.8 |

Available materials :

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface treatment:

|

Aluminum parts |

Stainless Steel parts |

Steel parts |

Brass parts |

|

Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

|

Color Anodized |

Passivating |

Oxide black |

chrome plating |

|

Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

|

Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

|

Brushing |

Electrophoresis black |

Carburized |

Powder coated |

|

Polishing |

Oxide black |

Heat treatment |

|

|

Chroming |

Powder Coated |

||

|

Heat Treatment |

Tempering |

Hardening |

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details

|

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Manufacturing Companies for Deep Draw Process - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong, The product will supply to all over the world, such as: Yemen, Slovenia, Nigeria, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

-

Professional Design Cnc Precision Machining Com...

-

Newly Arrival Metal Fence Parts - Machining Se...

-

Cheap price Cnc Machining Machines - stainless...

-

Fast delivery Aluminium Machine Part - High Pr...

-

2020 China New Design Screw For Meat Grinder Pa...

-

Reasonable price for Magnesium Die Casting - c...