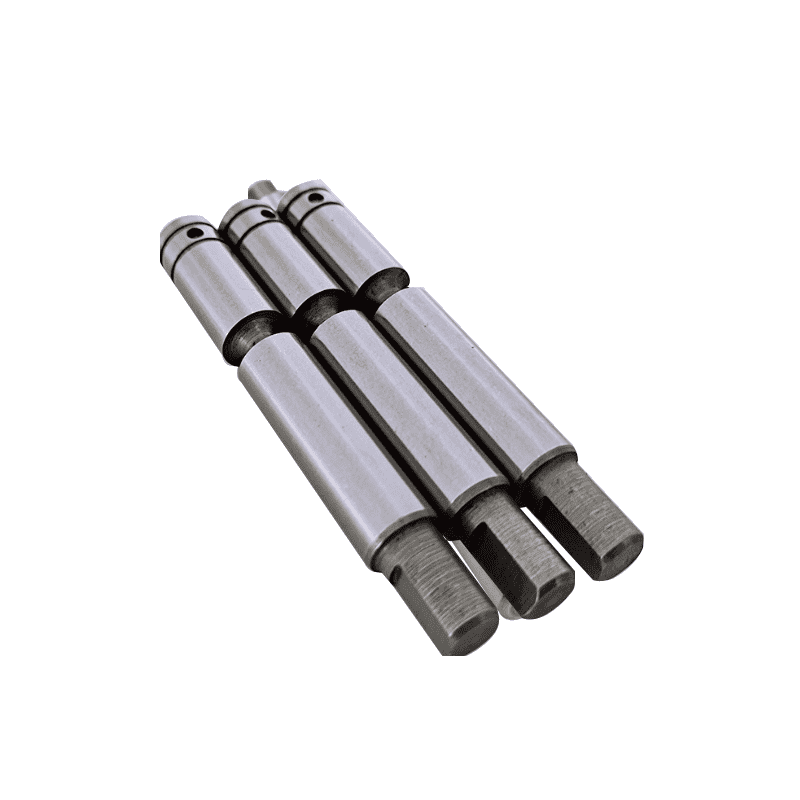

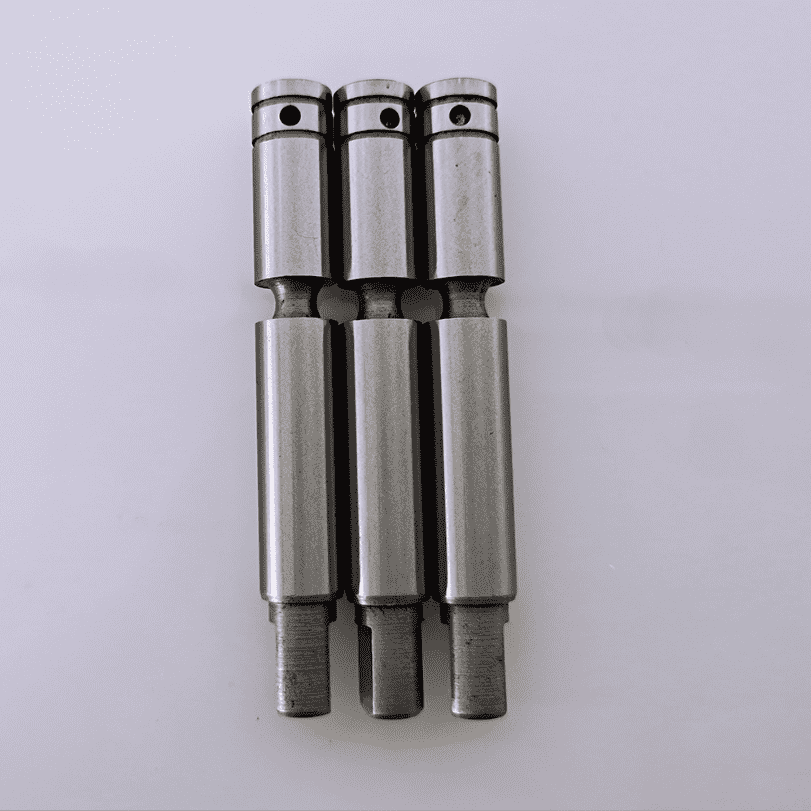

Chinese Professional Cnc Lathe Machining Process - Automotive Oil Shaft – Daohong Detail:

Professional Information

|

Product name |

Spline gear |

|

Material |

C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless steel and so on as per your requests. |

|

Processing |

Forging,Machining,Hobbing,Milling,Shaving, Grinding,Heat treatment…… |

|

Heat Treatment |

Carburizing,Induction,Flame,Nitriding…… |

|

Main Machines |

Gear Hobbing Machines,Gear Shapers(Gealson,Moude), lathe, gear Shaving machines, gear millling, gear grinding Machines and CNC centers…. |

|

Why choose us |

•100% manufacturer

• Rich production experience •Advanced GEAR Machine •Strict Quality Control System •Flexible MOQ •Punctual delivery •Excellent and Experienced Team |

Regular Materials And Heat Treatment

|

Regular Materials and Heat Treatment |

|||||

|

GB/JB |

DIN |

JIS |

SAE/AISI |

Case Hardening |

Case Hardness |

|

40CrNiMo |

34CrNiMo6 |

SNCM439 |

4340 |

Nitriding |

46-50HRC |

|

20CrMo |

20CrMo44 |

SCT42 |

4119/4118 |

Carburizing |

42-45HRC or 55-60HRC |

|

20CrNiMo |

– |

SNCCM220 |

8620 |

Carburizing |

55-60 HRC or 58-62 HRC |

|

20CrMnTi |

– |

– |

– |

Carburizing |

55-60 HRC |

Heat Treatment Cycle: Carburizing /Nitriding → Normalize → Quench → Clean → Temper → Shot Blast

|

Precision Grade , Process Methods and Application Standard : GB 10095-88,DIN 3961-78;ISO 1328-75/GB 10095-88;JIS 1702-74; AGMA 39003-71

|

|||||

| Precision grade |

Grade 5 |

Grade 6 |

Grade 7 |

Grade 8 |

Grade 9/10 |

| Module range | Gleason M10∼M40 | Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

| Outside Dia(max) |

φ1500mm |

Φ2000mm |

Φ2000mm |

Φ3000mm |

Φ3000mm |

| Final Process |

fine grinding |

fine grinding or shaving |

grinding, shaving , lapping |

shaving |

– |

| Teeth Surface Roughness |

Ra 0.8 μm |

Ra 0.8 μm |

Ra 1.6 μm |

Ra 1.6-3.2 μm |

Ra 3.2-6.3 μm |

| Application |

Measuring gear

|

locomotive

|

craneforging machinetractors,trucksuniversal reducer |

crane farm machinery forging machine tractors,trucks universal reducer |

crane farm machinery forging machine mine machinery tractors |

| Why Choose US | •100% manufacturer |

• Rich production experience

|

•Advanced GEAR Machine

|

•Strict Quality Control System

|

•Flexible MOQ •Fast delivery

|

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details |

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Chinese Professional Cnc Lathe Machining Process - Automotive Oil Shaft – Daohong, The product will supply to all over the world, such as: Bolivia, Comoros, Turkey, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!