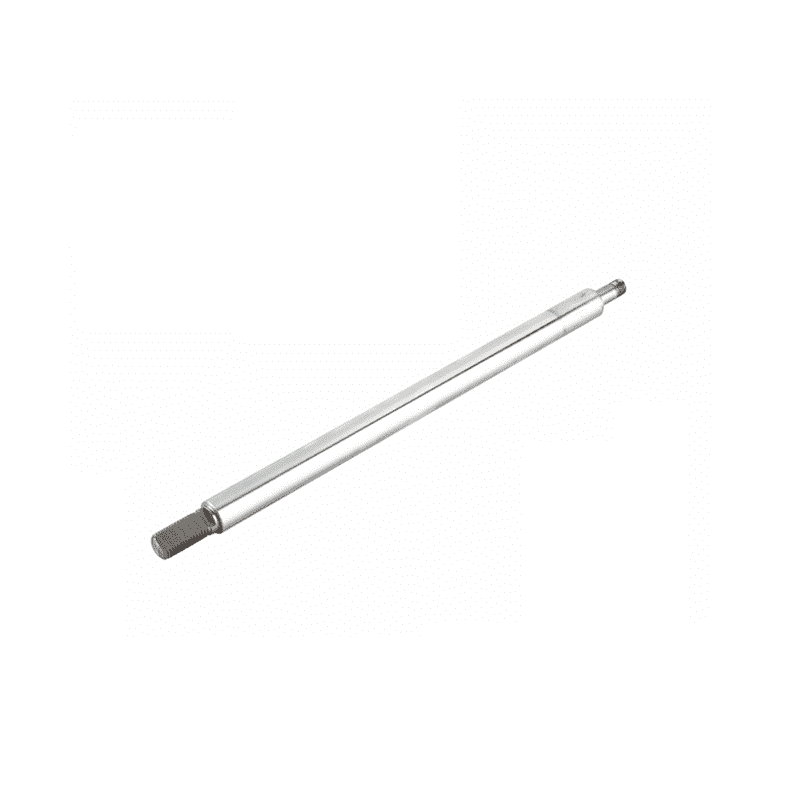

2020 High quality Brass Forged Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. |

|

Diameter |

0.1-25mm |

|

Length |

Customization |

|

Roughness |

Ra0.4-Ra0.8 |

Available materials :

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface treatment:

|

Aluminum parts |

Stainless Steel parts |

Steel parts |

Brass parts |

|

Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

|

Color Anodized |

Passivating |

Oxide black |

chrome plating |

|

Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

|

Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

|

Brushing |

Electrophoresis black |

Carburized |

Powder coated |

|

Polishing |

Oxide black |

Heat treatment |

|

|

Chroming |

Powder Coated |

||

|

Heat Treatment |

Tempering |

Hardening |

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details

|

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of 2020 High quality Brass Forged Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong, The product will supply to all over the world, such as: Doha, Algeria, Australia, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

-

Fixed Competitive Price Cnc Plastic Machining S...

-

High definition Turning Parts - Cnc Precision ...

-

Factory source Cnc Stone Machining Center - In...

-

Chinese Professional Aluminum Frame Parts - St...

-

2020 High quality Aluminum Fence Parts - Corro...

-

China New Product Sheet Metal Forming - Corros...