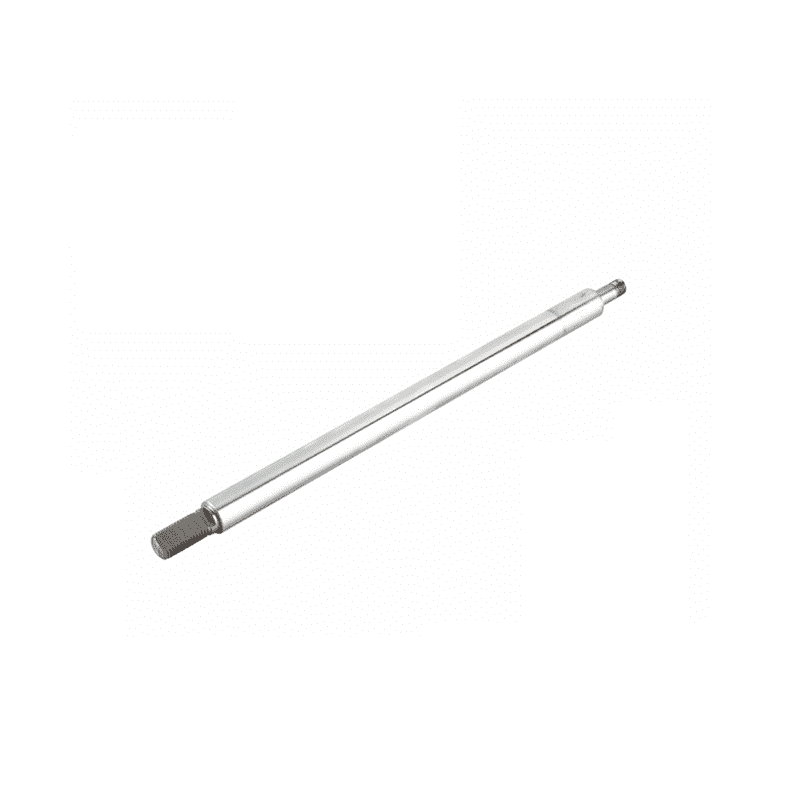

2020 High quality Brass Forged Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. |

|

Diameter |

0.1-25mm |

|

Length |

Customization |

|

Roughness |

Ra0.4-Ra0.8 |

Available materials :

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface treatment:

|

Aluminum parts |

Stainless Steel parts |

Steel parts |

Brass parts |

|

Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

|

Color Anodized |

Passivating |

Oxide black |

chrome plating |

|

Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

|

Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

|

Brushing |

Electrophoresis black |

Carburized |

Powder coated |

|

Polishing |

Oxide black |

Heat treatment |

|

|

Chroming |

Powder Coated |

||

|

Heat Treatment |

Tempering |

Hardening |

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details

|

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for 2020 High quality Brass Forged Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong, The product will supply to all over the world, such as: Ecuador, America, European, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

Well-designed Big Machine Parts - stainless st...

-

Reasonable price for Grass Cutter Spare Parts -...

-

Factory Outlets Cnc 4th Axis - stainless steel...

-

OEM/ODM Factory Cnc Machining Treepanning - gr...

-

High Performance Mold Components Punch Die - F...

-

High Quality Die Casting Profile - High qualit...